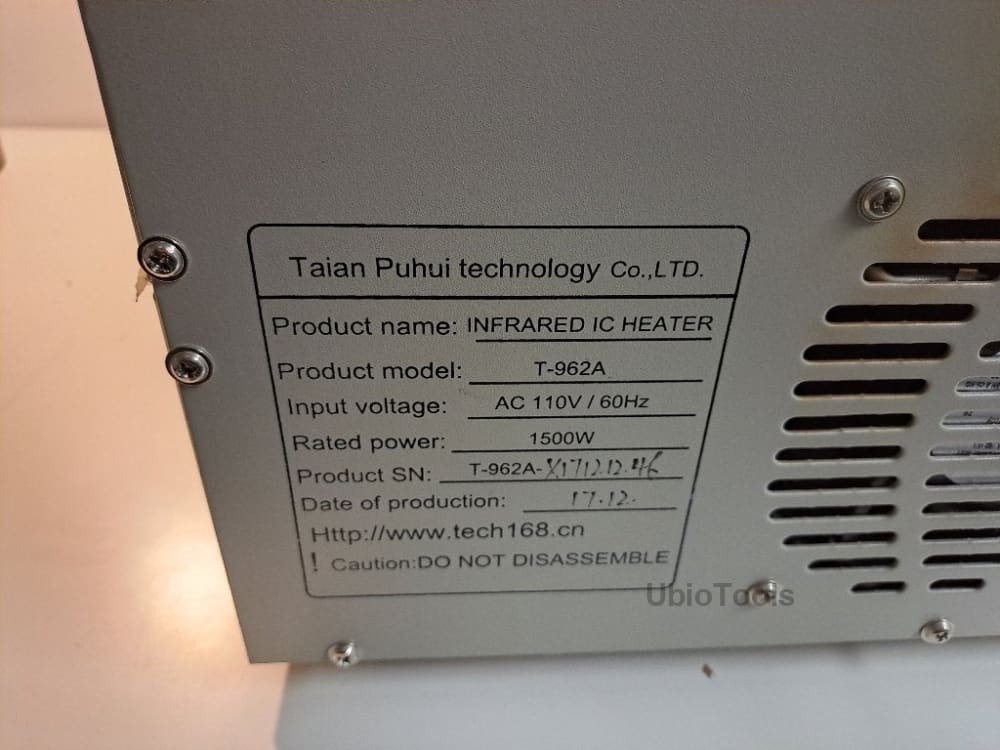

Puhui

INFRARED IC HEATER

INFRARED IC HEATER

Couldn't load pickup availability

The Puhui INFRARED IC HEATER T-962 A is a micro processor controlled reflow-oven. It can be used for effectively soldering various SMD and BGA components.The whole soldering process can be completed automatically and it is very easy to use, This machine uses a powerful infrared emission and circulation of the hot air flow, so the temperature is being kept very accurate and evenly distributed.

A windowed drawer is designed to hold the work-piece,and allows safe soldering techniques and the manipulation of SMDBGA and other small eletronic parts mounted on a PCB assembly. The T962 may be automatically rework solder to correct bad solder joints,remove/replace bad components and complete small engineering models of prototypes.

Features:

- A large infrared soldering area: Effective soldering area:300×320mm;this increases the usage range of this machine drastically and makes it an economical investment.

- Choice of different soldering cycles: Parameters of eight solderng cycles are pre defined and the entire soldering process can completed automatically from Preheat,Soak and Reflow through to cool down.

- Special heat up and temperature equalization with all designs: Uses up to 1500 Watts of energy efficient Infrared heating and air circulation to re-flow solder.

- Ergonomic design,practical and easily operated: Good build quality but at the same time light weight and a small footprint allows the T962 to be easily bench positioned transported or stored .

- Large number of available functions: The T962 can solder most boss-eyed or double-face PCB boards small parts,for example CHIP,SOP,PLCC,QFP,BGA etc.It is the ideal rework solution from single runs to on-demand small batch production.

Specs:

● Rated Power: 1500W

● Processing Time: 1~8 min

● Power Supply: AC110V/50~60HZ

Comments:This item turns on and heats. All buttons are working.

Condition: Good

Location: Miami, US

Weight (lbs / kg): 30.8 / 14

Dimension (in / cm): 17 x 14.5 x 10.2 / 43×37×26cm

Share